Why the Creality Ender 3 V3 Could Be the Best 3D Printer for You

Creality Ender 3 V3 Review: When discussing 3D printers, one name consistently appears in the conversation: the Ender 3 in 2024. This printer has garnered a massive following, and for good reason. Many users swear by its reliability, customizability, and affordability. However, my experience with Creality, the manufacturer of the Ender 3, has been mixed, primarily due to past issues with their customer support. Nevertheless, when allowed to review the new Creality Ender 3 V3, I approached it with an open mind.

Creality Ender 3 V3 Pros and Cons

| Affordable price ($279.99) at Micro Center | Potential software issues with slicing |

| Larger build volume (220x220x250 mm) | Filament tube compression during homing |

| High printing speed (up to 600 mm/s) | Requires occasional tinkering |

| Higher build surface temperature (110°C) | Inconsistent print reliability |

| Core XZ design (faster x-axis movement) | Customer support issues |

| Easy assembly (two main pieces) | Possible filament breakage with older filament |

| Good print quality when functional | Initial gantry wobbliness during setup |

| Open-source based Clipper software | Software performance not as refined as competitors |

| Automatic belt tensioning |

Why People Love the Creality Ender 3 V3 Review

From my discussions with numerous Ender 3 owners, it is clear that the printer’s affordability and customizability are significant factors driving its popularity. The original Ender 3 remains available for purchase, which is a testament to its enduring appeal. When Creality offered me the chance to try the new Creality Ender 3 V3, I decided it was worth exploring whether this updated model could live up to the high expectations set by its predecessor.

My Previous Experience with Creality

I am not a huge fan of Creality, mainly due to my experience with the Ender 7. Despite enjoying the printer itself, the machine bricked when I tried to install a BLTouch sensor, and dealing with Creality’s customer support was a frustrating ordeal. Many reviews online echo my sentiment regarding their customer support. Nonetheless, I aimed to evaluate the Creality Ender 3 V3 objectively.

Setting Expectations for the Ender 3 V3

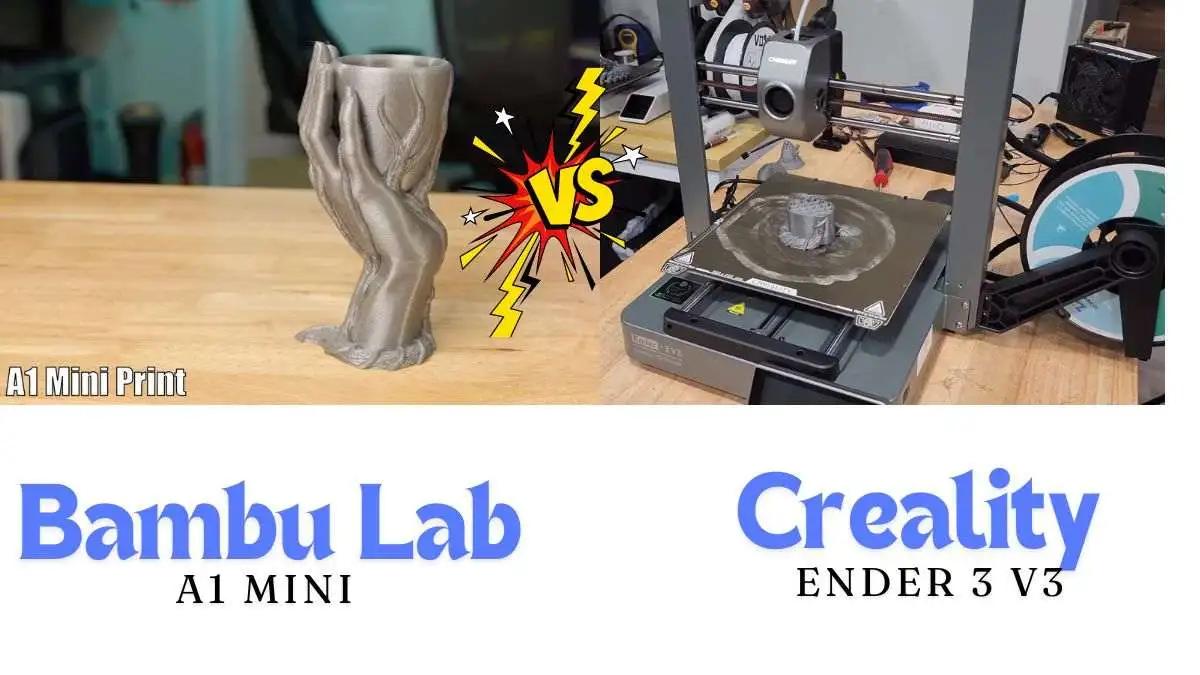

Before even receiving the Creality Ender 3 V3, I set my expectations based on its price point of $279.99 at Micro Center. A comparable printer in this price range is the A1 Mini from Bamboo Labs, which I use frequently. Despite my preference for Bamboo Labs, I aimed to remain unbiased in this review.

Key Advantages of the Ender 3 V3

One significant advantage of the Creality Creality Ender 3 V3 is its build volume. While the A1 Mini offers a 180x180x180 mm build area, the Ender 3 V3 provides a larger 220x220x250 mm space. This additional space can be crucial for many projects, preventing the need to redesign models to fit within a smaller build volume.

Another benefit is the Creality Ender 3 V3’s speed. It can reach up to 600 mm/s, compared to the A1 Mini’s 500 mm/s. Although the A1 Mini claims a theoretical maximum speed of 10,000 mm/s, this is practically unachievable given its build area. Thus, the Ender 3 V3’s slightly higher speed is a noteworthy advantage.

The Creality Ender 3 V3 also features a build surface that can reach up to 110°C, whereas the A1 Mini is limited to 80°C. This higher temperature capability allows for a broader range of materials to be used.

Creality Ender 3 V3 Full Specifications

| Build Volume | 220x220x250 mm |

| Input Shaping | Yes (G-sensor included) |

| Product Dimensions | 358x374x498 mm |

| Leveling Mode | Auto Leveling |

| Package Dimensions | 541x418x245 mm |

| Display Screen | 4.3″ HD color touch screen |

| Net Weight | 7.83 kg |

| Mainboard | 32-bit |

| Printing Speed | ≤600 mm/s |

| Connectivity | WiFi |

| Acceleration | ≤20000 mm/s² |

| Printable File Format | G-code |

| Printing Accuracy | ±0.2 mm |

| Power Loss Recovery | Yes |

| Layer Height | 0.1-0.35 mm |

| Runout Sensor | Yes |

| Filament Diameter | 1.75 mm |

| AI Camera | Optional |

| File Transfer | USB drive / WLAN / Creality Cloud |

| Rated Voltage | 100-120V~, 200-240V~, 50/60Hz |

| Nozzle Diameter | 0.4 mm |

| Rated Power | 350 W |

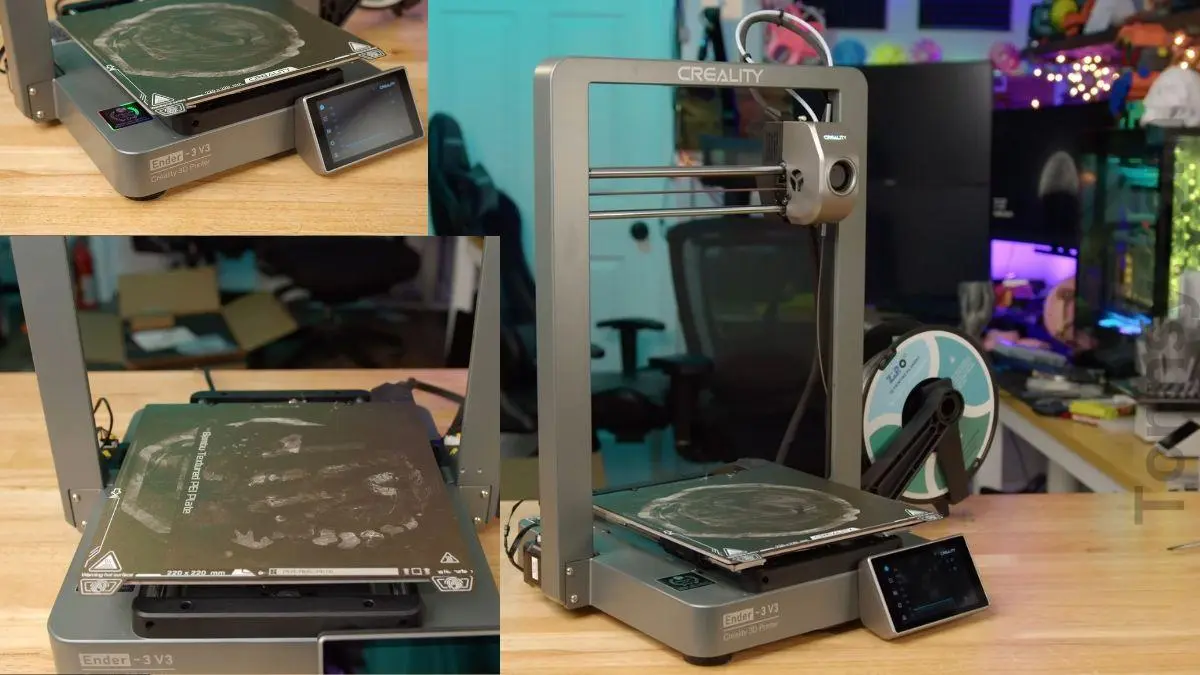

| Build Surface | PEI flexible build plate |

| Slicing Software | Creality Print |

| Nozzle Kit | Quick-swap nozzle (hardened steel tip) integrated with heatbreak |

| File Formats for Slicing | STL, OBJ, 3MF |

| Extruder | New high-speed direct drive extruder |

| Supported Filaments | PLA, TPU, PETG, ABS, PLA-CF, PETG-CF, CR-carbon |

| Nozzle Temperature | ≤300°C |

| Heatbed Temperature | ≤110°C |

| UI Languages | 中文/English/Deutsch/Español/Français/ Italiano/Português/Русский/ Turkish/日本語/한국어 |

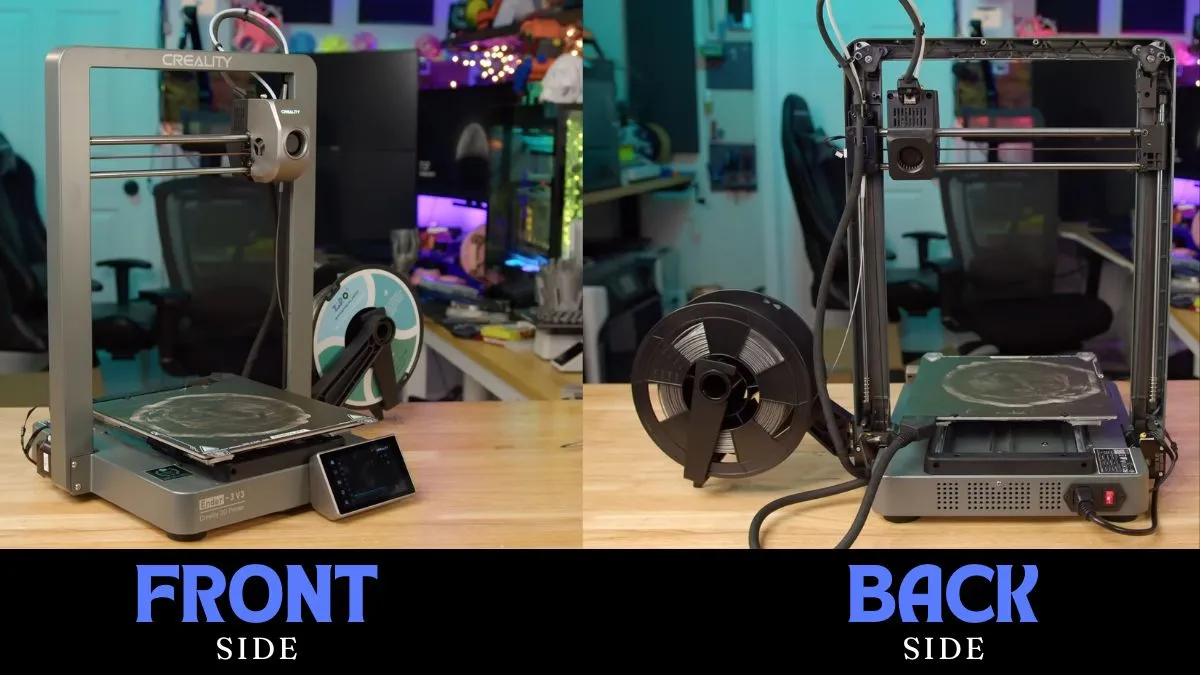

Core XZ Design and Assembly

The Creality Ender 3 V3 introduces a Core XZ design, a first for me. Unlike Core XY machines, which I am familiar with, the Core XZ setup is new territory. This design eliminates the need for ball screws, potentially making the x-axis quicker.

Assembly of the Creality Ender 3 V3 is straightforward. Gone are the days of piecing together numerous parts. The printer comes in two main pieces: the gantry and the base. Attaching these components and plugging in the necessary connections is all that’s required.

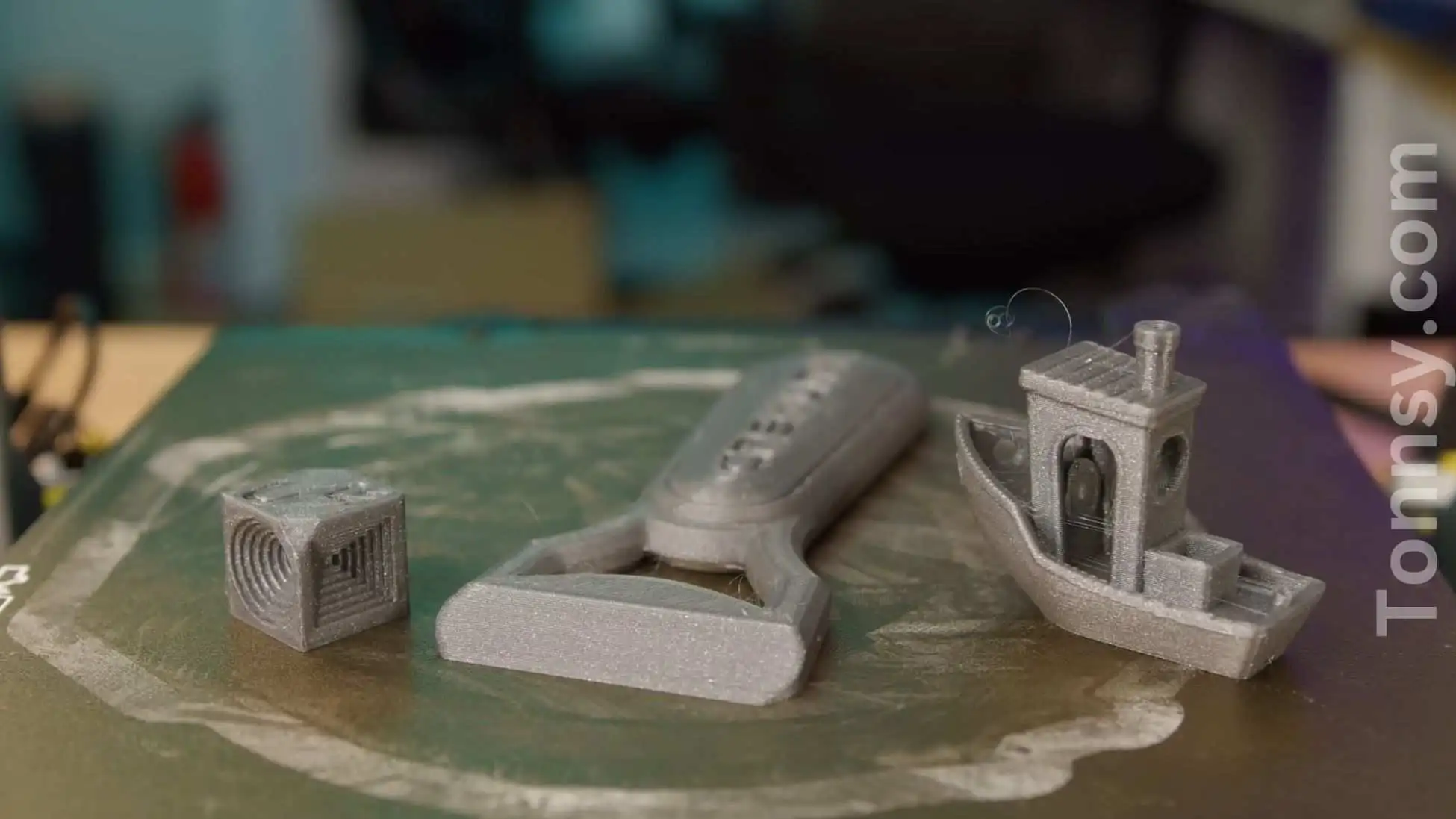

Initial Impressions and Print Quality

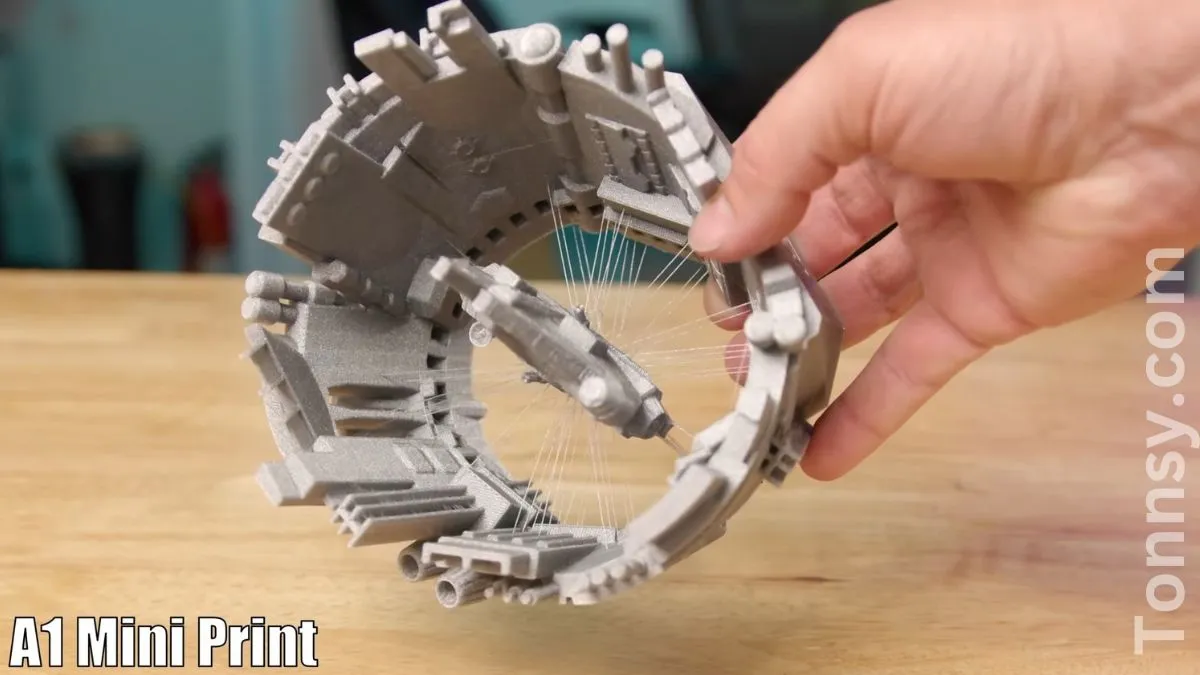

After setting up the Creality Ender 3 V3, I began with some pre-loaded test prints. The printer impressed me with its speed and print quality for a bed-slinger type. However, I encountered an issue with the filament tube setup. The tube is positioned in front of the gantry’s crossbar, causing it to compress during the homing sequence. While this did not cause immediate problems, it could potentially lead to filament breakage, especially with older filaments.

Testing Larger Prints

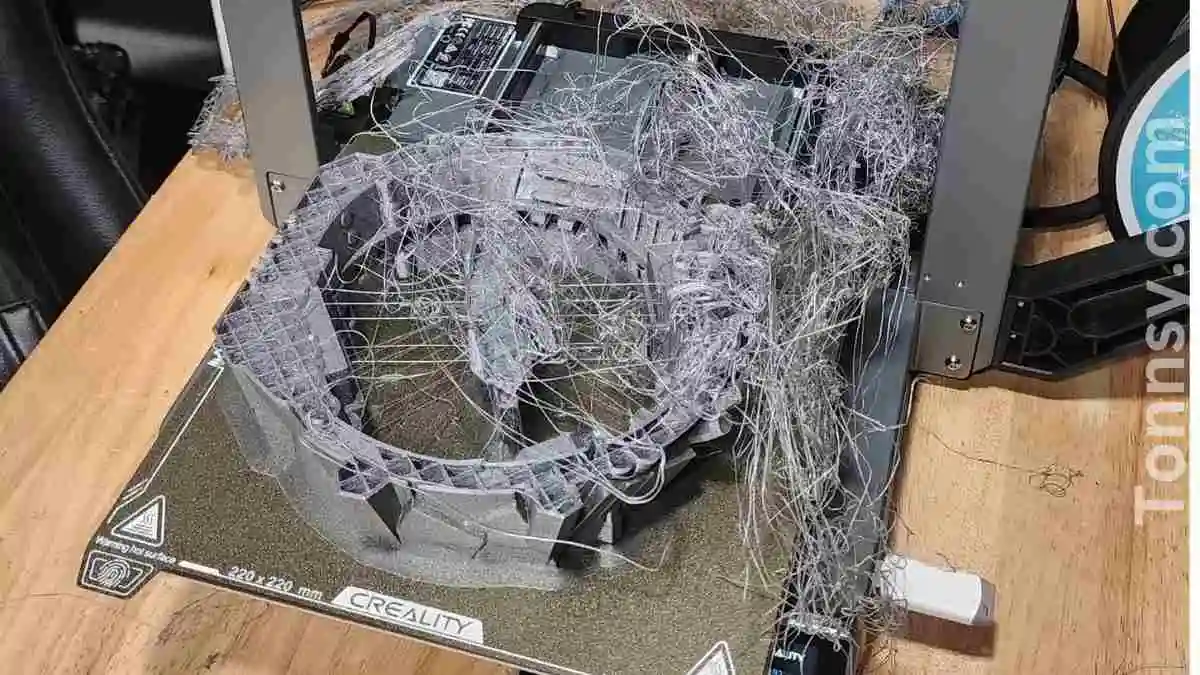

To push the printer further, I attempted a larger print: a Millennium Falcon model. Unfortunately, this print failed twice, seemingly stopping at the same layer height both times. Despite these setbacks, I decided to try a simpler model, a vase, which also failed to print correctly. These issues led me to suspect a problem with the slicing software rather than the hardware.

15 Interesting Features in the Ender 3 in 2024

- Affordable Entry Point: The Creality Ender 3 V3 is priced at around $279.99 at Micro Center making it a cost-effective option for both beginners and experienced users.

- Large Build Volume: It offers a substantial build volume of 220x220x250 mm, providing more space for larger prints compared to many other printers in its price range.

- High Printing Speed: The Creality Ender 3 V3 can reach printing speeds of up to 600 mm/s, allowing for quicker print jobs.

- Higher Temperature Capability: Its build surface can heat up to 110°C, which is higher than many printers in its class, enabling the use of a wider variety of filaments.

- Core XZ Design: This unique design improves x-axis movement speed and reduces the need for ball screws, which are common in other designs.

- Easy Assembly: The printer comes in two main parts that are easy to assemble, making it accessible even for those new to 3D printing.

- Automatic Belt Tensioning: The Creality Ender 3 V3 features belts that automatically maintain the correct tension, reducing the need for manual adjustments.

- Open-Source Firmware: It runs on Clipper, an open-source firmware, allowing for greater customization and control by advanced users.

- Customizability: The Ender 3 series is known for its wide range of available upgrades and modifications, allowing users to enhance and personalize their printer.

- Strong Community Support: With a large user base, there is extensive community support, including forums, social media groups, and tutorials.

- Good Print Quality: When properly calibrated, the Creality Ender 3 V3 produces high-quality prints, comparable to more expensive models.

- Pre-Loaded Test Prints: The printer comes with pre-loaded models for immediate testing, helping users quickly assess its capabilities.

- Compact Design: Despite its large build volume, the Creality Ender 3 V3 maintains a relatively compact footprint, suitable for small workspaces.

- Energy Efficiency: The printer is designed to be energy-efficient, helping to reduce overall power consumption during operation.

- Versatile Filament Compatibility: It supports a wide range of filament types, including PLA, ABS, TPU, and PETG, making it versatile for different printing needs.

Final Attempts and Conclusion

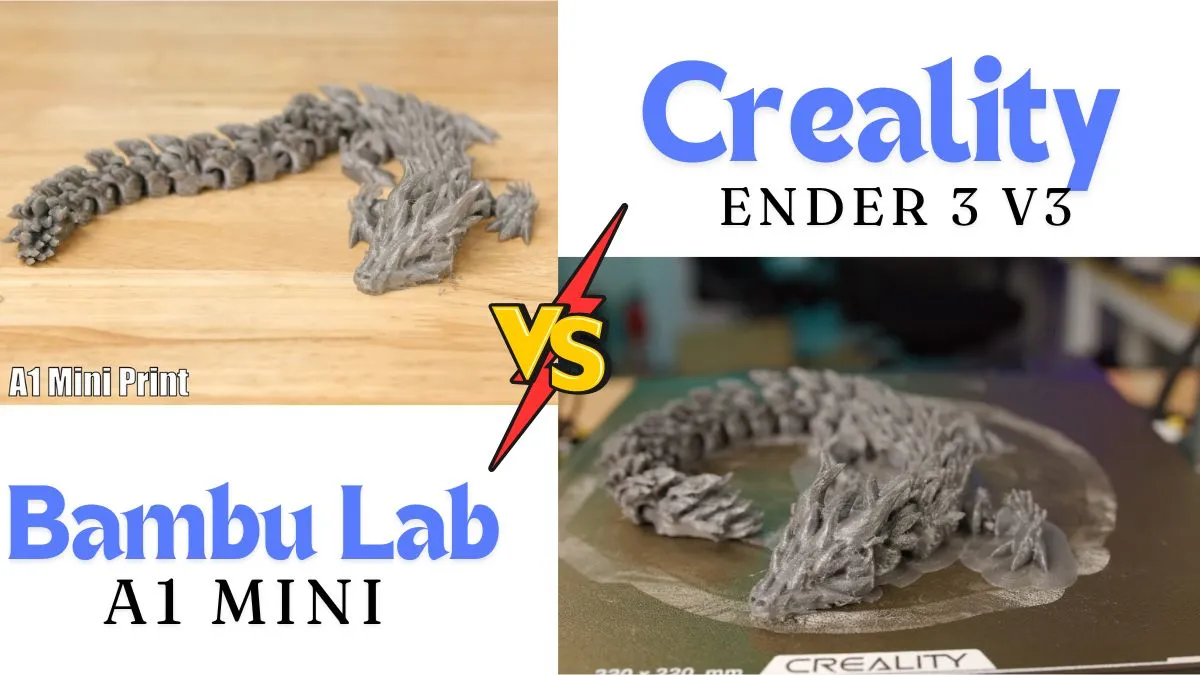

Despite my frustrations, I did achieve success with a different model, a bendy dragon. Both the Creality Ender 3 V3 and the A1 Mini produced excellent prints, although the Creality Ender 3 V3 added an unnecessary brim.

Ultimately, my experience with the Creality Ender 3 V3 was mixed. While the printer demonstrated excellent print quality and speed when it worked, the frequent failures and software issues were significant drawbacks. For users who enjoy tinkering and customizing their printers, the Creality Ender 3 V3 offers great potential. However, for those like me who prefer a reliable, hassle-free experience, I recommend considering alternatives like the Bamboo Labs A1 Mini.

In the Creality Ender 3 V3 Review conclusion, the Creality Ender 3 V3 has its strengths and weaknesses. Its affordability, build volume, and speed make it an attractive option for many users. However, potential software issues and the need for occasional tinkering may deter those seeking a more straightforward 3D printing experience.

Creality Ender 3 V3 Review With Video

FAQs

Is the Ender 3 V3 reliable?

The Ender 3 V3 is generally reliable when properly set up and maintained. However, some users have reported occasional issues with software and print consistency, which may require troubleshooting and adjustments.

What are the downsides of the Ender 3 printer?

The downsides of the Ender 3 printer include occasional software issues, inconsistent print reliability, and poor customer support. It may also require manual adjustments and tinkering.

How fast can the Ender 3 V3 print?

The Ender 3 V3 can print at speeds of up to 600 mm/s.

Can the Ender 3 catch fire?

While rare, any 3D printer, including the Ender 3, can potentially catch fire due to electrical issues or overheating components. Proper maintenance, monitoring, and using the printer within recommended guidelines significantly reduce this risk.

Is the Ender 3 noisy?

Yes, the Ender 3 can be noisy during operation, especially due to its stepper motors and cooling fans. However, noise levels can be reduced with upgrades such as quieter fans and stepper motor drivers.